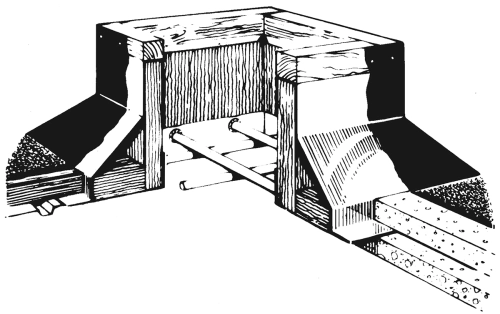

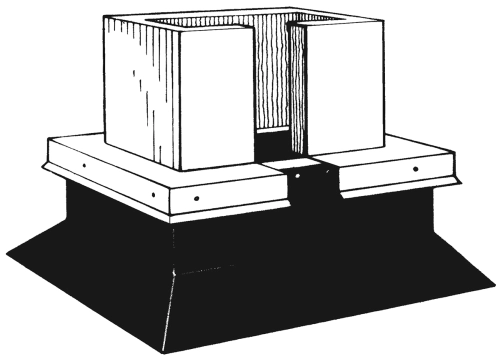

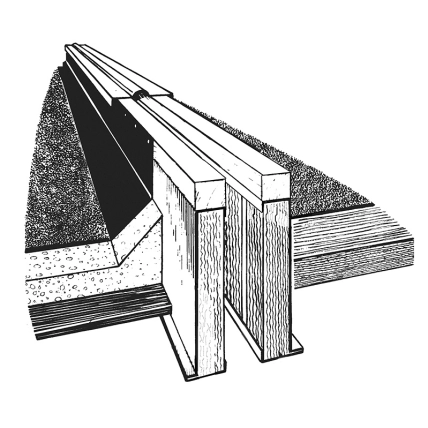

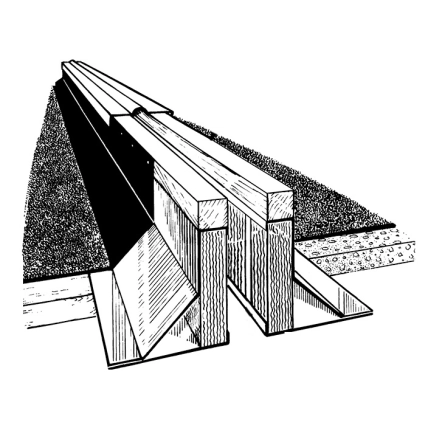

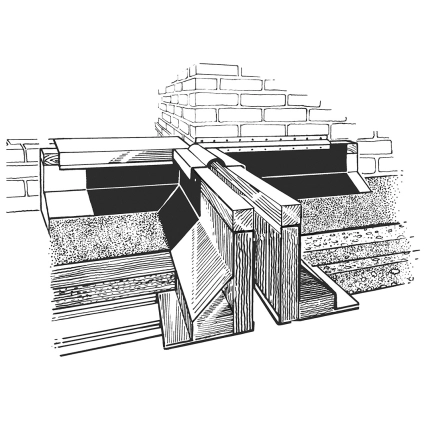

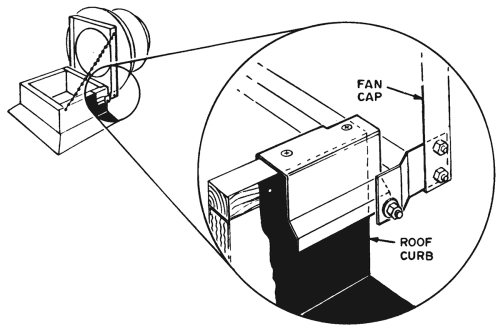

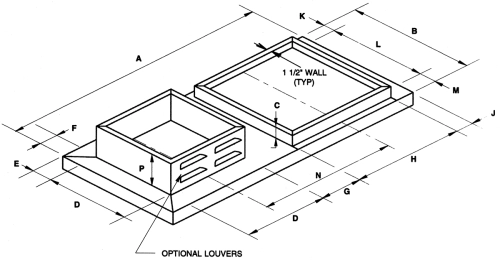

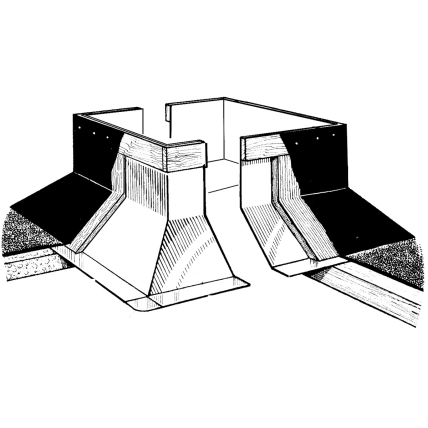

Roof Curbs

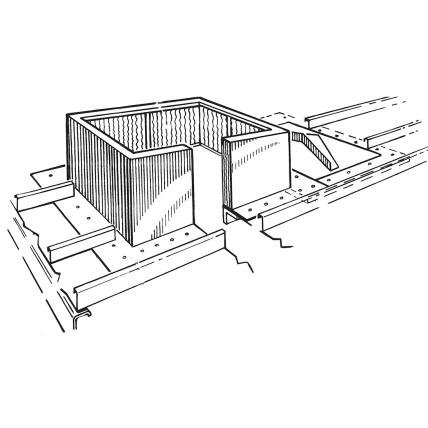

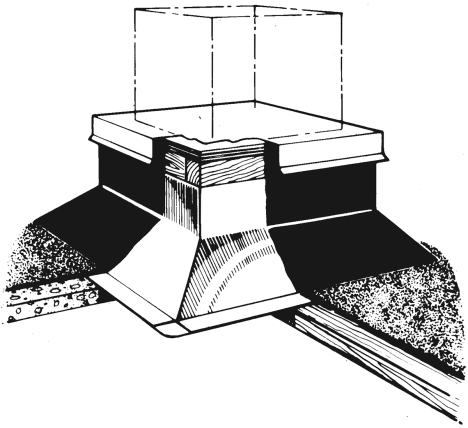

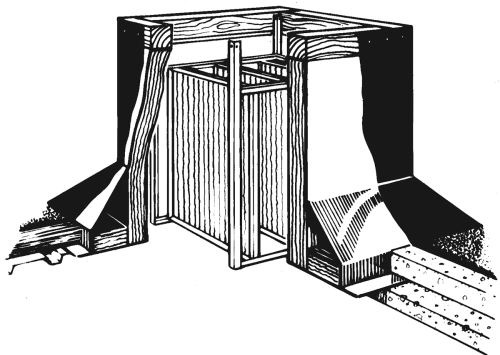

Specify prefabricated roof curbs and related products by a roof curb manufacturer (not with, or by, the equipment manufacturer). Specify prefab roof curbs for use with all roof penetrations and roof mounted equipment including, and not limited to, HVAC units, duct openings, pipe penetrations, power roof exhauster, intake and relief vents, flues, or job fabricated items. All roof curbs, equipment rails, pipe and duct mounting pedestals, and pipe penetration systems to be specified together, bought by one contractor, and installed by one contractor. All curbs to be provided by one roof curb manufacturer.

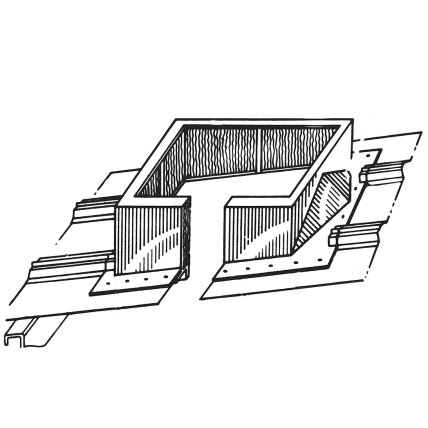

Close Filters

Filters